Oil in biomass: a step-change for bioenergy production?

By John Dyer, Robert Mullen, and Kent Chapman

April 2012

To help meet the rapidly growing demand for biofuels, scientists and policy makers envision that a variety of agricultural, municipal, and forest-derived feedstocks will be used to produce “second-generation” biofuels, whereby carbon-rich materials are either fermented to produce ethanol or combusted under oxygen-limiting conditions to produce “syngas” (which can be used to produce a variety of biofuels or chemicals). Alternatively, these same carbon-rich materials can be fractionated to recover energy-dense molecules such as oils from a variety of nonfood sources, including algae(Table 1).

Table 1. Current and potential feedstocks for biofuel production

| Source Fuel type | Fuel Type |

| Corn | Ethanol |

| Sugarcane | Ethanol |

| Soybean | Biodiesel |

| Rapeseed | Biodiesel |

| Perennial plants on degraded lands | Ethanol/syngas/electricity |

| Crop residues (e.g., corn stover) | Ethanol/syngas/electricity |

| Sustainably harvested forest materials | Ethanol/syngas/electricity |

| Double crops/mixed cropping systems | Ethanol/biodiesel/syngas/electricity |

| Municipal and industrial wastes | Ethanol/biodiesel/syngas/electricity |

| Recovery of oils from food industry | Biodiesel |

| Algae | Biodiesel |

Biotechnology will certainly play an important role in the further development of biofuels because it offers creative approaches to solving some of the most vexing problems associated with biofuels. For example, some of the main challenges for production and use of biofuels are that current agricultural practices simply cannot deliver sufficient amounts at low-enough prices to meet the massive demand. These problems could be addressed, in part, by engineering crops to yield significantly greater carbon and energy content.

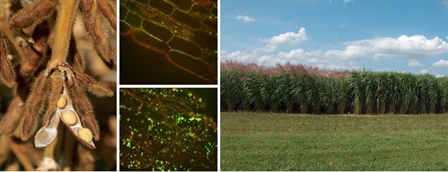

Biotechnology offers multiple opportunities to achieve that goal. For instance, plants might be engineered for enhanced cellulose production (and reduced lignin content) for ethanol production. Alternatively, or in addition, crops might be developed to accumulate higher amounts of energy-dense lipids, including vacuole-imported secondary metabolites, cuticular waxes on aerial surfaces, or oils (triacylglycerols) in leaves (see inform 22:631–634, 2011) and other vegetative parts of plants. This latter scenario is particularly attractive because the biomass of (nonseed) aerial parts of plants (e.g., leaves and stems) is generally far greater than the amount accounted for by seeds. As such, a rapidly growing perennial grass, such as Panicum (commonly referred to as switchgrass) or Miscanthus, might be developed with the capacity to accumulate oil in leaves (Fig. 1)

FIG. 1. Production of oil in plant leaves. Shown on the left is an image of mature soybean seeds, a major source of biodiesel in the United States, and on the right, the high-yielding perennial grass Miscanthus. The micrographs in the middle show images of wild-type Arabidopsis leaves (top panel), and leaves that have been engineered to contain a mutation in the cgi58 gene (bottom panel), which results in the hyper-accumulation of lipid droplets (seen here as green-stained punctae). Middle panels reprinted with permission from the Proceedings of the National Academy of Sciences (Disruption of the Arabidopsis CGI-58 homologue produces Chanarin-Dorfman-like lipid droplet accumulation in plants, James, et al., PNAS 107:17833-17838, 2010). Left and right panel images provided by the USDA-ARS Image Gallery and Bill Deen (University of Guelph, Canada), respectively.

The harvested biomass could then be used for the recovery of both the oil for biodiesel and the cellulosic residues for ethanol production. Alternatively, this energy-rich biomass (oil has twice the energy content of carbohydrate on a mass basis) could be combusted to produce syngas or electricity.

In the next section, we highlight new and emerging research that suggests we are in fact moving closer to realizing the potential of increasing the amounts of recoverable, renewable energy from bioengineered crop plants.

Biotechnology for producing oils in nonseed plant biomass

Although seeds are the primary site of oil synthesis and storage in plants, there is increasing appreciation that other plant parts can also synthesize and accumulate significant amounts of oil. For instance, the single greatest source of vegetable oil in the world is the oil palm tree, which produces ~35% of the world’s vegetable oil. Palm oil is obtained from both the seed (palm kernel) and the fleshy fruit tissue (mesocarp) that surrounds the seed and that contains up to 90% oil by weight. Olive oil is similarly derived from the oil-rich mesocarp tissues surrounding the seed. Other pertinent examples of nonseed sources of oils include the “oil firewood” plant Tetraena mongolica Maxim, which contains up to 5% oil in stem tissues (dry weight), and the yellow nutsedge plant (Cyperusesculentus), which contains about 24% (dry weight) oil in underground storage organs known as tubers.

Whereas all of these examples provide precedents for production of oil in nonseed parts of the plant, they also involve specialized organs for oil synthesis and storage. Thus, it would be difficult to engineer this type of oil accumulation process into a biomass crop such as Miscanthus. On the other hand, all plant cell types, including those in leaves and stems, have the capacity to synthesize some oil, specifically triacylglycerols (TAG), and scientists are now trying to exploit this observation to significantly ramp up the amounts of TAG in nonseed plant parts through various engineering techniques. TAG are conveniently packaged into lipid droplets for storage in the cytosol of cells.

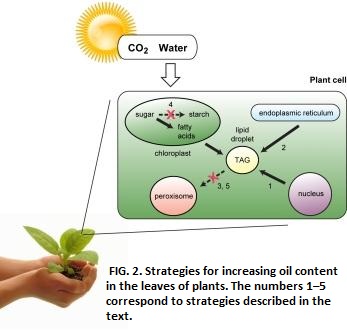

Two general approaches have been explored thus far. The first involves more “global” efforts to reprogram leaves for oil synthesis by modifying the normal actions of DNA transcription factors. Transcription factors are proteins that bind to DNA in order to induce the expression of a gene or suite of genes whose encoded product(s) (e.g., a protein) serve a particular purpose within the cell. Several years ago transcription factors called LEC1, LEC2, and WRI-1 were shown to control the expression of genes involved in oil synthesis in developing plant seeds. Remarkably, the ectopic expression of these transcription factors in leaves reprogrammed them for the synthesis of oil, such that not only did TAG oil content increase, but fatty acids normally found exclusively in seed oils were also present in leaf tissues (Fig. 2, strategy 1). Using transcription factors in this manner, however, is not without its shortcomings, since reprogramming a leaf to become more seed-like can have negative effects on normal leaf structure, development, and function.

A second approach to increase oil content in nonseed tissues is to alter fatty acid metabolism in leaves in favor of oil production. For instance, the final step of TAG synthesis is catalyzed by an enzyme called diacylglycerol acyltransferase (DGAT), and multiple studies have demonstrated that overexpression of this often rate-limiting enzyme in developing seeds can boost their oil content by up to 25% (wt/wt). Scientists also have overexpressed DGAT in leaves, resulting in a notable increase in oil content (Fig. 2, strategy 2). In another approach, scientists blocked the ability of plants to break down fatty acids altogether, and this also caused an increase in oil content of leaves under certain growth conditions (Fig. 2, strategy 3). Similarly, inhibition of a key step in starch biosynthesis in plant leaves, to reduce the flow of carbon into starch, also led to an accumulation of TAG (Fig. 2, strategy 4). Lastly, mutating a gene in Arabidopsis (considered to be a model system for studies of plant biology) that regulates multiple aspects of fatty acid metabolism in plant cells, particularly the breakdown and turnover of TAG by peroxisomes (Fig. 2, strategy 5), produced a significant increase in oil content in plant leaves.

Although all of these approaches increase oil content in leaves, greater increases will likely come from combinations of approaches. One study recently reported a 5.8-fold increase in TAG accumulation, with a 9.5-fold increase in energy content in leaves by combining oil-specific transcription factors with a targeted reduction of starch biosynthesis.

Challenges for producing oil in biomass

Significant challenges remain for the use of biofuels as sustainable alternatives to fossil oil-derived fuels, such as the relatively high cost of biofuel production, competition with food-related practices (e.g., arable land and water usage), and the sheer differences in market size between agriculture and energy sectors.

Many technical challenges also remain, including those for producing oil in biomass. Our knowledge of oil synthesis in plant leaves and its regulation is still rudimentary. A significant amount of research is required to understand these processes better, especially in the context of bioenergy production. One example is that the normally low amounts of TAG present in leaf cells are thought to be a transient depot for fatty acids that can either be transferred in and out of cellular membranes or metabolized for energy, depending on the immediate needs of the cell or organism. How then does one “stabilize” the TAG pool so that it will accumulate as a “sink” in leaves, similar to how it accumulates in developing seeds? This might be accomplished by expressing structural proteins from plant seeds called oleosins that normally bind to and stabilize the TAG in specialized lipid droplets. It might also be important to modify the fatty acid composition of leaf-derived oil, which is in polyunsaturated fatty acids and thus might not be ideal for biodiesel production (but should not matter for either syngas production or direct combustion of the plant material to produce electricity).

Clearly, as we begin to understand more about how oils are produced and degraded in plant cells, there will be increasing opportunities to further enhance the energy content in the nonseed tissues of plants.

John Dyer is a research molecular biologist working at the US Department of Agriculture-Agricultural Research Service, US Arid-Land Agricultural Research Center in Maricopa, Arizona. He can be contacted at john.dyer@ars.usda.gov.

Robert Mullen is a professor and university research chair in the Department of Molecular and Cellular Biology at the University of Guelph, Ontario, Canada. He can be contacted at rtmullen@uoguelph.ca.

Kent Chapman is a professor of biochemistry and director of the Center for Plant Lipid Research at the University of North Texas in Denton, Texas, USA. He can be contacted at chapman@unt.edu.

information

Andrianov, V., N. Borisjuk, N. Pogrebnyak, A. Brinker, J. Dixon, S. Spitsin, J. Flynn, P. Matyszczuk, K. Andryszak, M. Laurelli, M. Golovkin, and H. Koprowski, Tobacco as a production platform for biofuel: overexpression of Arabidopsis DGAT and LEC2 genes increases accumulation and shifts the composition of lipids in green biomass, Plant Biotechnol. J. 8:277–287 (2010).

James, C., P.J. Horn, C.C. Richardson, S.K. Gidda, D. Zhang, R.T. Mullen, J.M. Dyer, R.G.W. Anderson, and K.D. Chapman, Disruption of the Arabidopsis CGI-58 homologue produces Chanarin–Dorfman-like lipodystrophy in plants, Proc. Natl. Acad. Sci. USA 107:17833–17838 (2010).

Ohlrogge, J., and K. Chapman, The seeds of green energy: expanding the contribution of plant oils as biofuels, The Biochemist 33:34–38 (2011).

Sanjaya, Durrett, T.P., Weise, S.E., and Benning, C. (2011) Increasing the energy density of vegetative tissues by diverting carbon from starch to oil biosynthesis in transgenic Arabidopsis. Plant Biotechnol J. 9:874—83.

Slocombe, S.P., J. Cornah, H. Pinfield-Wells, K. Soady, Q.Y. Zhang, A. Gilday, J.M. Dyer, and I.A. Graham, Oil accumulation in leaves directed by modification of fatty acid breakdown and lipid synthesis pathways, Plant Biotechnol. J.7:694–703 (2009).

The Billion Ton Update (www1.eere.energy.gov/biomass/pdfs/billion_ton_update.pdf).

The Renewable Fuel Standard (epa.gov/otaq/fuels/renewablefuels/index.htm).

10 projects that could transform plant-based oil production

In October 2011, the US Department of Energy’s Advanced Research Projects Agency-Energy announced plans to put $36 million into 10 biofuels-related projects that could transform plant-based oil production.

These Plants Engineered to Replace Oil (PETRO) projects push the limits of the amount of fuel that can be produced per acre or hectare of planted land by improving the efficiency with which plants use carbon and light, causing plants that currently produce sugar to produce oil instead, and maximizing oil storage in perennial grasses and woody biomass (see tinyurl.com/ARPA-E-PETRO).

University of Massachusetts, Amherst, is developing an improved oilseed crop that uses carbon more efficiently than traditional crops. The plant will incorporate features that significantly improve photosynthesis and also allow the plant to produce useful, high-energy fuel molecules directly within leaves and stems, in addition to seeds. This will allow a substantial increase in production of fuel per acre of planted land.

University of California, Los Angeles, is streamlining the process by which green plants convert carbon dioxide into sugar or biofuels. This technology could be applied broadly to improve yields of grain and biomass in crop plants.

Donald Danforth Plant Science Center’s Center for Enhanced Camelina Oil, St. Louis, Missouri, is engineering camelina with several genes that allow the plant to use light more efficiently, increase its carbon uptake, and divert more energy to the production of oil, which is stored in seeds and is convertible to fuels. The goal is to combine all of these genes into one engineered variety of camelina, and to prepare it for field trials.

Texas Agrilife Research at Texas A&M University, College Station, is trying to make photosynthesis more efficient by redirecting otherwise wasted energy in plants into energy-dense fuel molecules. The fuel will be readily separated from the plant biomass through distillation.

Lawrence Berkeley National Lab, Berkeley, California, is developing tobacco plants with leaves that contain fuel molecules via engineered traits that confer hydrocarbon biosynthesis, enhanced carbon uptake, and optimized light utilization. The tobacco will be grown using advanced cultivation techniques to maximize biomass production.

Arcadia Biosciences, Inc., Davis, California, is modifying a number of genes involved in oil biosynthesis to induce grasses to produce vegetable oil. Arcadia’s technology will yield biomass comprising 20% oil by weight and can be transferred into highly productive energy crops such as sorghum and switchgrass.

University of Illinois at Urbana-Champaign is engineering sugarcane and sorghum to produce and store oil instead of sugar. The team will optimize the intensity of the leaf color to more efficiently capture and use sunlight, improving energy yields by up to 50% compared to conventional crops. The resulting plants will be crossbred with the energy grass Miscanthus to increase their geographic range of cultivation.

North Carolina State University, Raleigh, is engineering the oilseed crop camelina with traits that increase the yield per acre of biodiesel. The project incorporates both an alternative way to capture carbon from air and features that allow the plant to accumulate larger quantities of vegetable oil and other fuel molecules in oilseeds. When combined, the fuel molecules plus vegetable oil isolated from the plant can be converted into a fuel mixture that is comparable to diesel or jet fuel.

Chromatin, Inc., Chicago, Illinois, is engineering sweet sorghum, a plant that produces large quantities of sugar and requires less water than most crops, so that it can accumulate the fuel molecule farnesene. Genes from microbes and other plants will be incorporated into sorghum to allow the plant to produce up to 20% of its biomass as farnesene, which can be readily converted into a type of diesel fuel. Farnesene will accumulate in the sorghum plants similar to the way in which sugar accumulates in sugarcane.

University of Florida, Gainesville, is increasing the production of turpentine, a natural liquid biofuel isolated from pine trees. The pine tree developed for this project is designed both to increase the turpentine storage capacity of the wood and to increase turpentine production from 3% to 20%. The fuel produced from these trees would become a sustainable domestic biofuel source. Production of 100 million gallons of fuel per year from less than 25,000 acres of forestland is predicted.