Improving food packaging, October 2022

By Rebecca Guenard

In This Section

- Raman spectroscopy for edible oil analysis, June 2024

- Begin at the end when isolating plant proteins, May 2024

- Microalgae’s impact on human and animal nutrition, April 2024

- Finding purpose and profit from waste, March 2024

- A low-cost, effective green extraction method, February 2024

- Establishing specialized nutrition in China, January 2024

- The disparity between protein sources and their nutritional value, November/December 2023

- Visualizing complex, multiphase food using confocal Raman microscopy, October 2023

- A more sustainable future begins with collaboration and data, September 2023

- Brain diets, July/August 2023

- Green coffee beans meet green tech, June 2023

- Fatty acid intake and inflammation, May 2023

- The Wild West of edible oils, April 2023

- The arc of preservation bends toward nature, March 2023

- Cloaking a cure: Lipid capsules save the world, February 2023

- From the farmers market to store shelves, January 2023

- Dogma vs. data: Rethinking linoleic acid, November/December 2022

- Improving food packaging, October 2022

- Proteins for meat alternatives: new competition for soy and wheat, September 2022

- Fish heads, fish heads: For biosurfactant production July/August 2022

- Mimicking mother’s milk June 2022

- Three paths forward for sustainable palm oil May 2022

- The continued struggle over biofuel feedstocks March 2022

- A new kind of plant breeding February 2022

- The new bio-based surfactant feedstock January 2022

- Lipid role in the immune system November/December 2021

- New essential dietary lipids? October 2021

- Gut Instincts September 2021

- Can computers make better plant-based foods? July/August 2021

- Poisson from a petri dish June 2021

- The latest additions to eco-friendly cleaning May 2021

- Preserving emulsions with plant-based antioxidants April 2021

- Developments in green surfactants for enhanced oil recovery March 2021

- Alternative base oils: a perspective March 2021

- The COVID-19 pandemic, one year later March 2021

- The green machine: commercializing microalgae products February 2021

- Bio-based (edible) oils: feedstock for lubricants of the future January 2021

- The latest on liposomes January 2021

- Fatty acids and athletic performance November/December 2020

- Where are lubricants headed November/December 2020

- New developments in vegetable oil materials science October 2020

- Agriculture at risk: preparing the oilseed industry for a warmer world September 2020

- Science highlights from a cancelled 2020 AM&E July/August 2020

- Managing your career in times of change June 2020

- Lipidomics comes of age May 2020

- Minimally processed oils April 2020

- The high-throughput frontier March 2020

- Nurturing innovation: how AOCS industries are fostering progress February 2020

- The trouble with studying omega-3s and the brain January 2020

- Understanding pulse anti-nutrients January 2020

- Digitizing manufacturing: how companies are using data to improve production November/December 2019

- Weaving together genetics, epigenetics, and the microbiome to optimize human nutrition October 2019

- Taking the cream out of ice cream September 2019

- Science highlights from St. Louis July/August 2019

- Biotechnology conquers consumer goods June 2019

- Cool characterization methods and where to find them May 2019

- Fermentation, the new protein supply chain April 2019

- Oleogels for drug delivery March 2019

- The complexity of clean-label cosmetics February 2019

- Rethinking plastic packaging January 2019

- Trends in synthetic and natural antioxidants for shelf life extension of meat and meat products November/December 2018

- The icing on the cake October 2018

- Enhancing oxidative stability and shelf life of frying oils with antioxidants September 2018

- Under arrest: investigating factors that govern partial coalescence July/August 2018

- Unconventional Oils June 2018

- Beauty from within May 2018

- Pulses rising April 2018

- Lessons learned from Hurricane Harvey March 2018

- Clean meat February 2018

- What makes your shortening suitable for fancy croissants, puff and Danish pastry? January 2018

- Strategic role of peanuts in sustainable global food security November/December 2017

- Science beyond borders: international student exchange October 2017

- Clean label: the next generation September 2017

- Science snapshots from Orlando July/August 2017

- Five new AOCS methods June 2017

- The whys and wherefores of life-cycle assessment May 2017

- China’s evolving edible oils industry April 2017

- The mysterious case of the arsenolipids March 2017

- Red palm oil February 2017

- The Highs and Lows of Cannabis Testing October 2016

- Chia: Superfood or superfad? January 2017

- Generational training divide November/December 2016

- Storage stability of roasted nuts and stabilization strategy using natural antioxidants September 2016

- Good vibrations: online and at-line monitoring of edible oils with vibrational spectroscopy July/August 2016

- Benchtop NMR spectroscopy for meat authentication June 2016

- Coconut oil boom May 2016

- Sink or swim: fish oil supplements and human health April 2016

- Pulsed electric field: groundbreaking technology for improving olive oil extraction March 2016

- Prescribing dietary fat: therapeutic uses of ketogenic diets February 2016

- Organogels of vegetable oil with plant wax January 2016

- The power of peptides November/December 2015

- Separation anxiety: membrane cleaning in the 21st century October 2015

- Using direct solid phase extraction to analyze persistent organic pollutants in oily food samples September 2015

- Big fat controversy: changing opinions about saturated fats June 2015

- Use of spent bleaching earth for economic and environmental benefit May 2015

- An introduction to cosmetic technology April 2015

- Food texture and nutrition: the changing roles of hydrocolloids and food fibers March 2015

- Scientists rank thousands of substances according to potential exposure level March 2015

- Clean smell does not always equal clean air February 2015

- Biotechnology: Using living systems to solve problems February 2015

- Flush to fuel January 2015

- 1970s fish oil study criticized January 2015

- Developing a high-performance, low-streak degreaser November/December 2014

- Detection, monitoring, and deleterious health effects of lipid oxidation November/December 2014

- Modified protein mimics taste and texture of fat October 2014

- Development of the first efficient membrane separations of cis fatty acids October 2014

- Regulatory updates on FSMA and combustible dust September 2014

- How enzymes are transforming manufacturing September 2014

- Two advances in biodiesel technology July/August 2014

- 2014 AOCS Annual Meeting & Expo July 2014

- Peanut genome sequenced June 2014

- A customized approach to frying oil June 2014

- Omics reveals subtle changes in carbon flux that lead to increased oil biosynthesis in oil palm May 2014

- Cannabis testing: a review of the current landscape May 2014

- Industrial hemp gaining traction April 2014

- Emulsions: making oil and water mix April 2014

- Lipid co-oxidation of proteins: One size does not fit all March 2014

- FSMA marches on March 2014

- Disruptive technology? Walmart’s “green” product line may signal a big change February 2014

- Pathways to novel chemicals February 2014

- Specialty lipids in pet nutrition January 2014

- EFSA releases preliminary report on occurrence of 3-MCPD in food January 2014

- Seven new biobased surfactant technologies November/December 2013

- Do oil color scales make you see red . . . or yellow? November/December 2013

- Shortage leads to green route to olefins October 2013

- Sesamol: a natural antioxidant for frying oil September 2013

- FSMA update September 2013

- Patent rights and biotech seeds July August 2013

- The other vitamin E July 2013

- Frac fever heats up June 2013

- Fat fight: Catch-22 for Western oleochemicals? June 2013

- Health and Nutrition News April 2013

- FDA asks for fees from industry to fund FSMA June 2013

- What does it take to start a biodiesel industry? April 2013

- What’s in a Claim? Would a Food Not Labeled “Natural” Taste as Sweet? March 2013

- Regulatory overview March 2013

- The preservative wars February 2013

- Plants producing DHA February 2013

- Swift response to paper on feeding GMO corn, glyphosate January 2013

- AOCS: supporting international standards January 2013

- TSCA and the regulation of renewable chemicals July August 2013

- trans Fatty acid content of foods in China January 2013

- A novel green catalytic process for biodiesel production from Jatropha November/December 2012

- The America Invents Act: Groundbreaking US patent law changes are here November/December 2012

- “Super Phos” esters: the key to higher-performance products November/December 2012

- Advances in field-portable mass spectrometers for on-site analytics October 2012

- EFSA sets upper intake level for LC-PUFA October 2012

- Malaysia: economic transformation advances oil palm industry September 2012

- High-oleic canola oils and their food applications September 2012

- Using enzymes to prepare biobased surfactants July/August 2012

- Oilseeds: at the center of food, water, and energy security July/August 2012

- Health & Nutrition News June 2012

- Hydrocolloids get personal June 2012

- The secrets of Belgian chocolate May 2012

- Plants “remember” drought, adapt May 2012

- The power of mass spectrometry in the detection of fraud April 2012

- Oil in biomass: a step-change for bioenergy production? April 2012

- The Future of LAB March 2012

- World supplies of rapeseed and canola likely to remain tight in the 2012/13 season March 2012

- Methods for differentiating recycled cooking oil needed in China February 2012

- Supercritical fluid-based extraction/processing: then and now February 2012

- Singapore: the place to be in 2012 February 2012

- The Food Safety Modernization Act and its relevance to the oilseed industry February 2012

- Oilseeds in Australia January 2012

- Hydrogen peroxide in home-care formulations November 2011

- A new generation of renewable fuels is on the horizon November 2011

- Omega-3 fatty acids: $13 billion global market October 2011

- Soy and breast cancer October 2011

- EU approves food labeling rules September 2011

- IOM panel recommends tripling vitamin D intake: Panel’s conservative approach receives criticism September 2011

- Self-assembly of lyotropic liquid crystals: from fundamentals to applications August 2011

- Sustainability watch July 2011

- Sustainability Watch July 2011

- Are algae really feasible as fuel? June 2011

- The trouble with crystal polymorphism June 2011

- Insect oils: Nutritional and industrial applications May 2011

- Reconstructing formulas April 2011

- US eggs now lower in cholesterol April 2011

- How to control eating behavior--in mice March 2011

- Maybe we don’t know beans March 2011

- Short- and long-term price forecasting for palm and lauric oils February 2011

- New 3-MCPD (glycidol ester) method February 2011

- Regulatory issues associated with the international oils & fats trade January 2011

- Point-counterpoint on UC Davis olive oil report January 2011

- Biomass--The next revolution in surfactants? December 2010

- One person’s response to a high omega-6 diet November 2010

- Crop residues as feedstock for renewable fuels November 2010

- Universal detectors for determination of lipids in biodiesel production October 2010

- New very long chain fatty acid seed oils produced through introduction of strategic genes into Brassica carinata October 2010

- Surfactants based on monounsaturated fatty acids for enhanced oil recovery September 2010

- Questioning the virginity of olive oils September 2010

- Dietary guidelines report released August 2010

- Keeping up with detergent chemistry August 2010

- News from the Expo floor July 2010

- Degumming revisited July 2010

- First high-GLA safflower oil on market June 2010

- AOCS 2.0 debuts June 2010

- Palm fatty acid distillate biodiesel: Next-generation palm biodiesel May 2010

- Palm oil pundit speaks May 2010

- What is unrefined, extra virgin cold-pressed avocado oil? April 2010

- The ultra-low-linolenic soybean market April 2010

- Dealing with the media: A cautionary tale March 2010

- Hempseed oil in a nutshell March 2010

- Carbon management 101: A conversation with Eric Jackson February 2010

- Giants of the Past: Hermann Pardun (1908-2009) February 2010

- Q&A with Bill Christie February 2010

- Update on Jatropha January 2010

- Unique properties of carbon dioxide-expanded lipids January 2010

- The market situation and political framework in Germany for biodiesel and vegetable oil December 2009

- Industrial oil crops-when will they finally deliver on their promise ? December 2009

- Chemically enhanced oil recovery stages a comeback November 2009

- Field-portable mass spectrometers for onsite analytics: What's next? October 2009

- To make biofuels, or not to make biofuels:That is the question. September 2009

- Melamine analysis at the forefront September 2009

- Global oil yields: Have we got it seriously wrong? August 2009

- Omega-3 fatty acid profiling and dietary forensics August 2009

- Oilseeds of the future part 3 July 2009

- The rise and fall of surfactants lore July 2009

- Oilseeds of the future: Part 2 June 2009

- Codex Alimentarius Commission update June 2009

- Raw material sources for the long-chain omega-3 market:Trends and sustainability. Part 3. May 2009

- Oilseeds of the future: Part 1 May 2009

- Chloroesters in foods: An emerging issue April 2009

- Raw material sources for the long-chain omega-3 market: Trends and sustainability. Part 2. April 2009

- Synthetic HDL created March 2009

- Raw material sources for the long-chain omega-3 market:Trends and sustainability. Part 1. March 2009

- A convenient way to increase legume intake February 2009

- Vitamin E’s safety controversy January 2009

- Universal mechanism of aging uncovered? January 2009

- Is it time to reconsider the role of saturated fats in the human diet? April 2022

October 2022

- For decades, the world has benefitted from plastic, but the material is difficult to recycle and has been building in the environment since its invention.

- More research indicates that plasticizers and PFAS have detrimental health effects when used in proximity to food where they leach in an contaminant the products.

- Investment in bioplastics in on the rise, but some are concerned that these materials represent yet another demand on agricultural land already slotted for food and biofuel production.

For all the concern consumers have over the food they eat, new research indicates they also have cause to worry about its containers. Plasticizers are “ending up in our food, in our bodies, and are leading to serious and irreversible health effects,” said Ami Zota, an associate professor at the George Washington University’s Milken Institute School of Public Health in Washinton, DC (https://tinyurl.com/44ac5bk7).

Ortho-phthalates, often referred to as “phthalates,” are chemicals used in plastic products like food packaging or other minor food contact uses such as components of adhesives, lubricants, and sealants.

In July, the Journal of the American Medical Association Pediatrics published an analysis of National Institute of Health data from more than 6000 pregnant women in the United States. The results showed that women with a high level of phthalate metabolites in their urine were as much as 16 percent more likely to experience preterm labor (http://doi.org/10.1001/jamapediatrics.2022.2252).

Plastic packaging maintains the safety and quality of our food, but the material has contributed to concerns about human health and the environment for decades. Researchers are eager to develop packaging that inhibits microbial contamination and lipid oxidation while also coming from a natural source that decomposes quickly when turned into waste.

So far, commercial bioplastic frontrunners include polylactic acid (PLA) and polyhydroxyalkanoates (PHA)—a class of compounds belonging to the polyhydroxyester family of 3-, 4-, 5- and 6-hydroxy alkanoic acids. These materials are made from the microbial fermentation of corn, sugar, or vegetable oils. Scientists are also testing packaging films made out of milled flours from a variety of crops.

“The food industry should consider implementing biopolymer packages as a natural

and environmental-friendly alternative to prolong the shelf life of sensitive foods,” said Cecilia Gabriela Riveros, of the National University of Cordoba, Argentina, and lead author of a paper on peanut flour biopackaging.

Biopackaging will need to withstand the fluctuation of ambient conditions encountered between product manufacture and product sale. The material must also protect a product for water and oxygen, while remaining inert and not leeching into food. Moreover, when the time is right, biopackaging should decompose quickly without a trace.

Whether new types of biopolymers are capable of the heavy-lifting of their synthetic counterparts remains a question. Researchers are testing natural materials in hopes of finding something that satisfies most of the requirements on the packaging checklist.

Half a century of plastic packaging accumulating in the environment is taking a toll. New biopackaging materials cannot be discovered too soon.

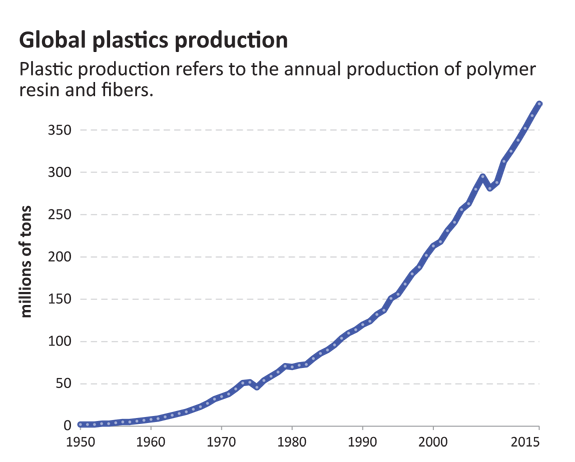

FIG. 1. In 1950 the world produced 2 million tons of plastic per year. Since then, annual production has increase nearly 200-fold, reaching 381 tons in 2015—equivalent to the mass of two-thirds of the world population. Source:ourworldindata.org.

Buried in plastic

“Worldwide, at least 8.8 million metric tons of plastic waste enter the world’s oceans each year — the equivalent of dumping a garbage truck of plastic into the sea every minute,” says a recent report by the US National Academy of Sciences (https://tinyurl.com/2p9y3eae).

In 2014, researchers used drones to calculate the size of the Great Pacific Garbage Patch, discovered in 1997. They found that in just under 20 years, the vortex of floating plastic waste had grown 100 times bigger.

The United Nations Environmental Program states that we produce about 400 million tons of plastic waste every year. They indicate that since the 1970s, the rate of plastic production has grown faster than that of any other material. And they say, if historic growth trends continue, global production of primary plastic is forecasted to reach 1,100 million tons by 2050 (https://www.unep.org/interactives/beat-plastic-pollution/).

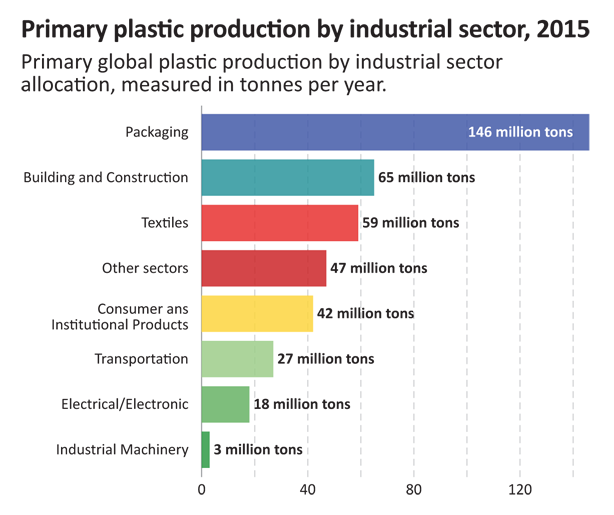

Roughly 45 percent of plastic produced goes into packaging which consumers frequently disposed of after a single use (https://ourworldindata.org/plastic-pollution). This is a problem since petroleum-based plastics do not decompose. They simply become smaller, microplastic. In fact, only 9 percent of all plastic every created has been broken down and recycled (https://tinyurl.com/mryyrae6).

FIG. 2. Packaging was the dominant use of primary plastics. Source:ourworldindata.org.

The inundation of plastic in our lives has resulted in the presence of plastic in our bodies. The microplastic in the ocean consumed by fish progress up the food chain eventually ending up on our dinner plates. Based on the amount of plastic in staple foods, researchers at the University of Newcastle in Australia estimate, that people ingest five grams of plastic each week, about the amount in a credit card (https://tinyurl.com/2p9ejk6b).

Research out of France this summer determined that 78 percent of bottled water produced there contains microplastics. And several studies have confirmed the presence of microplastics in human blood (https://doi.org/10.1016/j.envint.2022.107199).

Of course, plastic presents problems before becoming waste. Plasticizers and protective coatings leech from packaging into food.

“The FDA is aware of concerns raised about possible health effects of exposure to high levels of phthalates,” says the US Food and Drug Administration website. “However, at present the FDA is not aware of evidence that the dietary exposure to phthalates resulting from their use as food contact substances poses a safety risk.”

The FDA currently allows nine phthalates in food contact applications (eight for use as plasticizers and one for use as a monomer). Earlier this year three separate petitions were filed with the FDA requesting they revoke authorization of phthalates for food contact use. In May, the FDA rejected these petitions.

In July, they reopened “the comment period in response to a request to provide stakeholders with more time to fully consider the request for information and submit comments.” The deadline for this new comment period has not yet been announced.

The push for tighter regulations on phthalates coincides with growing US legislation at the state level to ban per- and polyfluoroalkyl substances (PFAS) from food packaging. Recent studies found that the grease-resistant packaging at prominent fast food chains contained over 100 parts per million fluorine from PFAS.

In 2020, the FDA initiated a three-year, voluntary program to phase-out PFAS. The agency is currently reviewing a petition from environmental groups calling for a PFAS ban in food packaging (https://tinyurl.com/yywkf2v7). The European Union, Denmark, and Canada have opted for a total ban of PFAS on all uses of the substances.

With so many negative aspects of plastic use in food packaging, it is no surprise that more investors are paying attention to bioplastics.

Growing investment in biopolymers

According to data from the market intelligence platform, i3 Connect, in 2022 corporations and venture capitalists invested $500 million in bioplastics manufacturing. Last year, investment peaked at $350 million. The bioplastics market is likely to reach $29 billion in the next five years, according to Zion Market Research (https://tinyurl.com/4xdx7skm).

The first bioplastic to get traction in the market is PLA. The material, made by fermenting sugar from corn and sugar cane, usually takes the form of compostable food service items such as plastic cutlery, clear cups, wrappers, and containers.

A joint venture between Cargill, with corporate headquarters in Minneapolis, Minnesota, USA and PTT Global Chemical, based in Thailand, resulted in the formation of NatureWorks, the world’s largest producer of PLA. The company’s plant in Blair, Nebraska, USA makes 150,000 metric tons of bioplastic pellets a year.

Although PLA is a popular bioplastic, it does not easily biodegrade. Due to its aliphatic polyester composition, a hydrolysis reaction will decompose the material, but that requires excess energy. To degrade naturally, PLA can be mixed with food waste in industrial composters or buried in landfills for a few decades (https://doi.org/10.1016/j.heliyon.2021.e07918).

In comparison, experiments with PHA show it can biodegrade in six months in marine environments (depending on the water temperature) and two years in soil.

NatureWorks partnered with a South Korean company called CJ Bio that manufactures PHA. CJ Bio is expanding its plant in Indonesia and is planning to build a large plant in the Americas, said Raj Kirsch, vice president of research and development, in an interview.

A company call Danimer Scientific, with headquarters in Bainbridge, Georgia, USA, recently expanded its PHA production capabilities by opening a second plant in Winchester, Kentucky. Opening a second facility makes Danimer the world’s largest PHA producer.

The company’s CEO says they have development projects to replace any plastic product imaginable with PHA made through a fermentation process using canola oil feedstock. The market supply of PHA will soon match PLA.

Edible films

Another way to approach the plastics problem, is to make food packaging out of substances that are safe for humans to eat.

Starch, a polysaccharide sourced from plants, has been formulated into a thermoplastic that can be remolded for use in food packaging. Unfortunately, these materials are sensitive to water absorption and do not exhibit the same level of function as plastics. When chemically modified, however, they can be blended with other biopolymers to improve their mechanical properties (https://doi.org/10.3390/polysaccharides3010007).

A research team in Argentina, led by Nelson Grosso, professor of food science and technology at the National University of Cordoba, is testing a blend of starch, protein, and lipids to evaluate their application as edible films. Since proteins, hydrolysates, and peptides contain polyphenols that act as antioxidants through free radical uptake and metal chelation, the researchers speculate that these compounds will result in the film effectively acting as a food preservative.

Among other oil seeds, one of the films the research produced was from chickpea flour. They milled the seeds and extracted the soluble sugars before film formation. The researchers stirred chickpea flour in a warmed, basic solution to dissolve the protein. Then, to plasticize the suspension, they added glycerol, let it cool and poured it into film molds. The films were smooth and transparent with a slight yellow tint. Grosso’s team stored the films for two months, periodically measuring a range of properties (https://doi.org/10.1111/1750-3841.15559).

Similar to other edible films under investigation, including blue corn flour, sesame protein and faba bean protein, they found that the films stiffened after 45 days of storage, potentially due to glycerol rearrangement. The migration of plasticizer in the film could result from a loss of moisture which coincides with the researcher’s observation that water vapor permeability decreased during the 60 day experiment.

However, the results of experiments on edible films were generally positive. The ordered hydrogen-bond network between the proteins and carbohydrates of edible films produce good oxygen and water barrier properties. By using flours that include a seed’s lipids, the team believes the hydrophobic molecules integrate into this matrix and provide an antioxidant benefit to food packaging.

In a more recent study, the team compared storage pouches made from edible films—in this case, defatted peanut flour—with the common synthetic plastics, polyethylene and polyvinyl alcohol. They filled the pouches with sunflower seeds which are susceptible to rancidity due a high concentration of unsaturated fatty acids. The researchers found that, after 30 days, the edible film pouch protected the sunflower seeds from becoming rancid better than the pouch made from polyethylene (https://doi.org/10.1002/aocs.12562).

FIG.3(a) Defatted peanut flour films and (b) defatted peanut flour pouch with sunflower seeds. Source: Riveros et al. JAOCS, 99, 153, 2022.

The main criticism of biopackaging, it is that making the materials requires taking up arable land to grow crops that could be used to produce food. According to a 2014 study, nearly a quarter of agricultural land producing grain was used for biofuels and bioplastics (https://doi.org/10.1016/j.rser.2014.01.056). Some experts say land use change must be considered when determining whether bioplastics are better for the environment, since the fertilizers and pesticides used to grow crops could actually increase pollution.

A representative for NatureWorks calls these concerns unfounded. Their company extracts sugar from corn that is then used in other products, like ethanol, sweeteners, or cooking oil. Although, Danimer’s feedstock is canola oil, they repurpose the crush into fertilizer and livestock feed.

So far, life cycle assessments of bioplastics have found that using bioplastics can reduce greenhouse gases on both the manufacturing and waste disposal side of the product. In terms of handling the waste, studies show carbon emissions could be lowered by up to 70 percent.

Ingesting oxidized dietary lipids routinely triggers the chronic inflammation that cascades into life-threatening disease. Food packaging is critical in preventing this type of chemical reaction from occurring. However, the packaging cannot negate this benefit by creating bigger problems long-term. Scientists now realize that for the past 70 years that is exactly what plastic has done. Recent research indicates that they are close to finding solutions that could reverse the damage.

About the Author

Rebecca Guenard is the editor-in-chief of INFORM at AOCS. She can be contacted at rebecca.guenard@aocs.org.